Inqanaba lesigaba senqanaba eliphindwe kabini liphinde lisebenze kwakhona

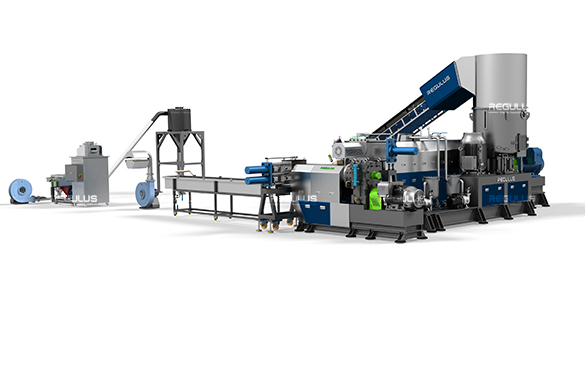

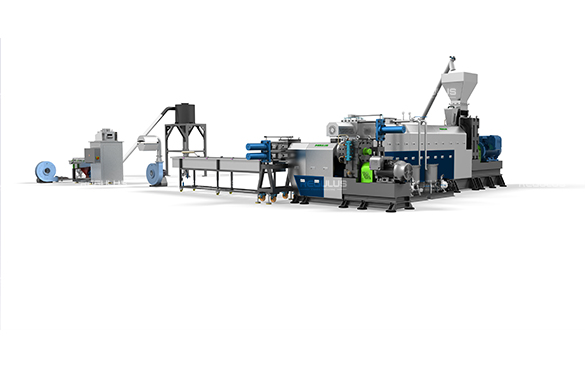

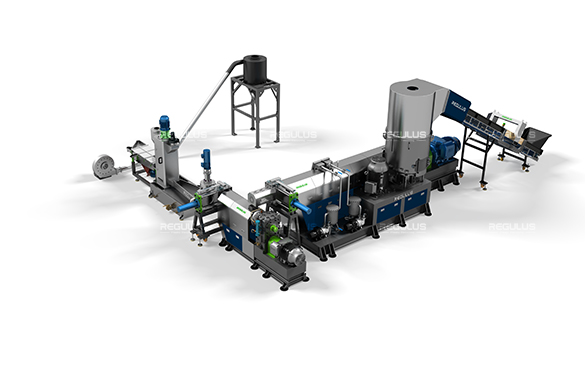

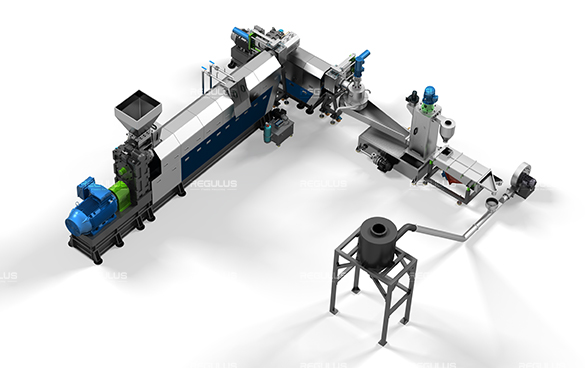

Inkcazo

| Ithagethi yokuphinda isebenze | I-HDPE, ldpe, i-PP, i-Bpp, CPP, i-PP, PC, PP, PU, i-PS, i-PS, i-ABS | |||||

| Ukuqulunqwa kwenkqubo | I-Belt Contwor, ukusika, isikrini esinye isikhafu, isiphoso,I-Pelletizer, Isixhobo sokupholisa amanzi, icandelo lokuphelelwa lizinyo, i-fan yokuhambisa, imveliso silo. | |||||

| Izixhobo zesikhafu | I-3ycrula (SACM-645), i-Bimetal (ngokuzithandela) | |||||

| L / d yescrew | 28/1, 30/1, 33/1, (ngokweempawu zokurisayikilisha) | |||||

| I-heater yomgodi | I-hearamic heater okanye i-heater ye-incrafred | |||||

| Ukupholisa i-barrel | Ukuphola komoya kubalandeli ngeempuphu | |||||

| Uhlobo lwePelletise | I-ring-ring ipellet / i-strands ye-pelleting / ipellet ephantsi kwamanzi | |||||

| Iinkonzo zobugcisa | Uyilo lweprojekthi, ulwakhiwo lomzi-mveliso, ufakelo kunye neengcebiso, thumo | |||||

| Imodeli yomatshini | Umlinganiso | L / d | Isikrelemnqa esinye | |||

| Ivolumu | Amandla eemoto | Ububanzi be-screw | Imoto yangaphandle | Isiphumo semveliso | ||

| (Ilitha) | (kW) | (mm) | (kW) | (kg / h) | ||

| I-Xy-85 | I-350 | 37 | 85 | 28 | 55 | I-150-250 |

| 10 | 22 | |||||

| I-XY-100 | I-500 | 55 | I-100 | 28 | 90 | I-250-350 |

| 10 | 30 | |||||

| I-Xy-130 | I-850 | 90 | I-130 | 28 | 132 | 450-550 |

| 10 | 45 | |||||

| I-Xy-160 | I-1100 | I-110-132 | I-160 | 28 | 185 | I-650-800 |

| 10 | 55 | |||||

| I-Xy-180 | I-1500 | 185 | I-180 | 28 | I-250-280 | I-900-1100 |

| 10 | 90 | |||||

Isikizi seplastiki yokuphinda sisebenze kwakhona ngeplastiki

Olu phawu luhlanganisayo kunye nenkqubo ye-Pelleting idibanisa ukusebenza, ukudityaniswa, ukufaka iplastiki kunye nokufaka inyathelo elinye. Ifakwe kwiPlastiki yePlastiki kunye neNkqubo yePelletive. Inkqubo ye-Absh Shrsh sisisombululo esinokuthenjwa kunye ne-raffia, i-raffia, iifilimu, iingxowa, iingxowa ezifudumeleyo kunye nempahla yokuphinda-phinda amatshini oqhubayo. Inokubonelela ngemveliso ephezulu kodwa ine-Preum ye-Partum esezantsi. Isicelo: PE, iphe, inkqi, i-ABS, XP, i-EPS, pvb.

Ukondla

Njengokuyilwa komgangatho, iziqwenga zeplastiki ezinje ngefilimu, ifiliment, iRaffia idluliselwa kwigumbi lokudibana ngomgaqo webhanti; Ukuphatha i-rolls 'scraps ze-rolls, ukuqengqeleka kwesixhobo sendlela yindlela yokutyisa. Imoto yemoto yebhanti yeDiscloor kunye neCoulling isixhobo sisebenzisana ne-inverter. Isantya sokusondla ibhanti ye-collor okanye ukuqengqeleka kwi-ngokuzenzekelayo isekwe ngokupheleleyo ngokusekwe kwindlela igumbi lomquluri.

Ukutyumza kunye nokudityaniswa

Umlinganiso uxhotywe ngesixhobo somoya. Ngomsebenzi woomatshini wenqanawa yeRotor kunye ne-stator ye-stactor ezantsi kwengqungquthela, iqondo lokushisa kunye nempahla iya kunyuka ngokuthe ngcembe emva kokusika kunye nokuthambisa, kunye nothuli kumphezulu we-quaw. Esi sixhobo sinokususa umswakama kunye nothuli, esiya kuthi sikuphephe ukusebenzisa ukusetyenziswa kwamandla ongezelelweyo ukujongana nomswakama.Inkqubo yokondla.

Iibhloko ze-rotatoctoct

I-blade ejikelezayo kunye ne-blade ehleliweyo inqumle izinto ezinamachaphaza amancinci. Ukufudumeza okufudumeleyo okuveliswa ziziqwengana ezijikelezayo ezijikelezayo kuya kubushushu ngawo kwaye zinciphise iiflethi.

Isikrelemnqa esinye

I-screw yethu eyodwa ye-screw ephumlwe ngobunono kwaye ihombisa izixhobo. Umntu wethu we-bi-bi-bi-bit excerrider une-anti-corrosion echasayo, enxiba ixesha lokuhlala elinganyangekiyo.

Imimandla ephindwe kabini yokuNgenisa

Ngeendawo zokungena eziphindwe kabini, ezikhawulezayo ezinje ngee-micros-molekyuli kunye nomswakama ziya kususwa ukusebenza kakuhle ukuphucula umgangatho weegranti, ngakumbi zilungele izixhobo ezibhaliweyo eziprintiweyo.

Uhlobo lwePlati

Icebo lohlobo lweplate lwenziwe ngohlobo oluqhubekayo kunye neepleyiti ezimbini zefiltha. Ubuncinci kukho icebo lokucoca icebo lokucoca xa isikrini sitshintshana nge-heater-ye-heater enomkhenkce kunye nokufudumeza

Akukho-spati ye-piston ye-piston

I-1.a rhoqo-iplate kunye ne-piston ye-piston itshintsha i-screen shansisher okanye i-piston ye-Speen Speest / i-Piston-Piston yesikhululo sinokufakwa kwintloko yentsebenzo yokuphefumla.

2.Long I-Screen Lindersime, I-Screen Screen Ferquency: Indawo yokuhlala ende ye-filitha ye-Wiling kwindawo yokucoca izifiso.

3. Kulula ukuyisebenzisa kunye nokungabikho kodidi: Utshintsho olulula kunye notshintsho olukhawulezileyo lwesikrini kwaye awudingi ukumisa umatshini wokuqhuba.

4.ngaphandle Ixabiso lokuSebenza eliphantsi.

Inyibiliki

Ukutsala i-rod ye-rod kusetyenziswa kakhulu, kunye nezinto ezingafunekiyo ezinje nge-PP, PE, i-PE, i-PE, i-PET, njl. Njl njl.

I-rannication yeplastiki ye-granung

I-1.Benater Dewaters viberation Ukudibanisa kunye nohlobo lwe-centrifal ye-centrigual debetals yangoku intsebenzo ephezulu kunye nokusetyenziswa kwamandla asezantsi.

2. I-Ceves ehlanganisiweyo: I-SEEves ifakiwe kwaye ilungiswe zizikrelemnqa endaweni ye-welding, ukuze utshintshe amaxabiso ngokulula kwixesha elizayo.

Inkqubo ye-granunter yeplastiki yokuphola

Isetyenziselwa ukususa umswakama ukusuka kwi-brace zeplastiki

Inkqubo yokusika i-granurounter

Isetyenziselwa ukusika imitya yeplastiki kumasuntswana

Isikrini sokugcwalisa

Isetyenziselwe ukwahlula ubungakanani be-sundeles zeplastiki