Isigaba esiphindwe kabini seplastiki

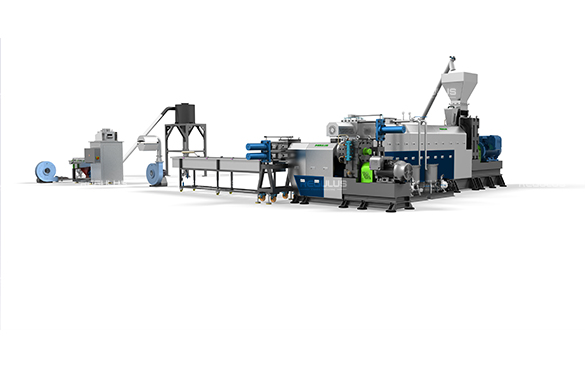

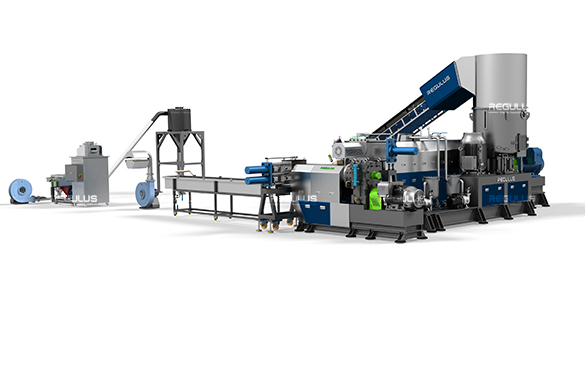

Inkcazo

| Ithagethi yokuphinda isebenze | I-HDPE, ldpe, i-PP, i-Bpp, CPP, i-PP, PC, PP, PU, i-PS, i-PS, i-ABS | |||||

| Ukuqulunqwa kwenkqubo | I-Screw Lorer, isikhafu esinye isikhafu, isiqulatho sokuqala, isidima sokukhumbula, isixhobo sokupholisa amanzi, i-Shuflor fan, imveliso yemveliso | |||||

| Izixhobo zesikhafu | I-3ycrula (SACM-645), i-Bimetal (ngokuzithandela) | |||||

| L / d yescrew | 28/1, 30/1, 33/1, (ngokweempawu zokurisayikilisha) | |||||

| I-heater yomgodi | I-hearamic heater okanye i-heater ye-incrafred | |||||

| Ukupholisa i-barrel | Ukuphola komoya kubalandeli ngeempuphu | |||||

| Uhlobo lwePelletise | I-ring-ring ipellet / i-strands ye-pelleting / ipellet ephantsi kwamanzi | |||||

| Iinkonzo zobugcisa | Uyilo lweprojekthi, ulwakhiwo lomzi-mveliso, ufakelo kunye neengcebiso, thumo | |||||

| Imodeli yomatshini | L / d | Isikrelemnqa esinye | ||||

| Ububanzi be-screw | Imoto yangaphandle | Isiphumo semveliso | ||||

| (mm) | (kW) | (kg / h) | ||||

| I-XY100 / 100 | I-100 | 28 | 75-90 | 200-300 | ||

| 10 | 22-30 | |||||

| I-XY120 / 120 | I-120 | 28 | I-90-110 | I-250-400 | ||

| 10 | 30-37 | |||||

| I-XY130 / 130 | I-130 | 28 | 132 | 450-550 | ||

| 10 | 45 | |||||

| I-XY160 / 180 | I-160 | 28 | I-160-200 | I-550-850 | ||

| 10 | 55 | |||||

| I-XY180 / 200 | I-180 | 28 | I-220-250 | I-800-1000 | ||

| 10 | 75 | |||||

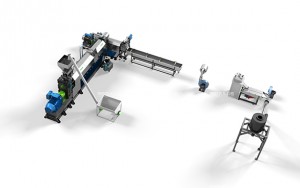

Inqanaba lesigaba senqanaba eliphindwe kabini liphinde lisebenze kwakhona

Ungcelele olukhawulezileyo oluqhelekileyo kunye nenkqubo ye-Pelleting yinkqubo ekhethekileyo nethembekileyo, ethembekileyo, ilungele umsebenzi wokuphinda usebenzise kwakhona kwaye uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde usebenze kwakhona. Idibanisa umsebenzi weplastiki kunye nokufaka inyathelo kwinyathelo elinye kwaye ilungele i-rerrind yorinds okanye i-flekes ye-PE / PP / ABS / i-PS njl.

Imveliso yokugqibela eveliswa ngumgca wesikrelemnqa omnye sikwi-pellets / igranules, inokubekwa ngqo kumgca wemveliso yefilimu, i-pump yokukhuphela isikhuselo seplastiki, njl

Umatshini wokutya okuphezulu

Iipuzzle okanye iiflethi ezinqabileyo, zidluliselwe kwi-screw enye i-Screw Trurder, emva koko, i-compress, i-shorties yenkqubo ye-vacuum, emva kokufumana igranugules. Kuxhomekeka kwiidayimitha ezahlukeneyo zesikrelemnqa, isikhundla esiqhelekileyo sinokugubungela ukusuka kwi-100kg / h ukuya kwi-1000kg / h, ukulayisha amandla emoto: 2.2 kw. Ukudlulisela umbhobho owenziwe ngezinto ezingenasinqwitha, ubukhulu be-Pipe Saner yi-2mm, ububanzi bemibhobho yi-102mm.

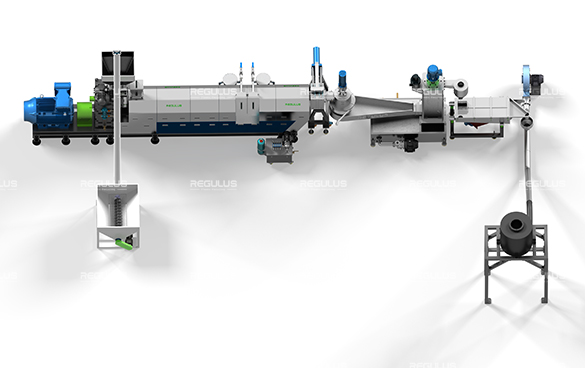

Iphambili (i-volumec)

Iya kusondla izinto kumthengisi. Kukho isikhafu esifunxayo ukuthintela ibhloko yezinto ezantsi komntu ofekileyo. Ukondla i-hopper enesalathiso senqanaba.

Ukuba ufuna ukudibanisa izixhobo, ii-feers zecala zikhethekile.

Isikrelemnqa esinye

I-screw yethu eyodwa ye-screw ephumlwe ngobunono kwaye ihombisa izixhobo. Umntu wethu we-bi-bi-bi-bit excerrider une-anti-corrosion echasayo, enxiba ixesha lokuhlala elinganyangekiyo.

Imimandla ephindwe kabini yokuNgenisa

Ngeendawo zokungena eziphindwe kabini, ezikhawulezayo ezinje ngee-micros-molekyuli kunye nomswakama ziya kususwa ukusebenza kakuhle ukuphucula umgangatho weegranti, ngakumbi zilungele izixhobo ezibhaliweyo eziprintiweyo.

Uhlobo lwePlati

Icebo lohlobo lweplate lwenziwe ngohlobo oluqhubekayo kunye neepleyiti ezimbini zefiltha. Ubuncinci kukho icebo lokucoca icebo lokucoca xa isikrini sitshintshana nge-heater-ye-heater enomkhenkce kunye nokufudumeza

Akukho-spati ye-piston ye-piston

I-1.a rhoqo-iplate kunye ne-piston ye-piston itshintsha i-screen shansisher okanye i-piston ye-Speen Speest / i-Piston-Piston yesikhululo sinokufakwa kwintloko yentsebenzo yokuphefumla.

2.Long I-Screen Lindersime, I-Screen Screen Ferquency: Indawo yokuhlala ende ye-filitha ye-Wiling kwindawo yokucoca izifiso.

3. Kulula ukuyisebenzisa kunye nokungabikho kodidi: Utshintsho olulula kunye notshintsho olukhawulezileyo lwesikrini kwaye awudingi ukumisa umatshini wokuqhuba.

4.ngaphandle Ixabiso lokuSebenza eliphantsi.

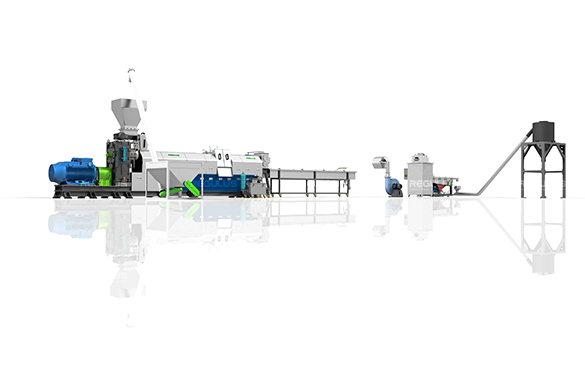

Inyibiliki

Ukutsala i-rod ye-rod kusetyenziswa kakhulu, kunye nezinto ezingafunekiyo ezinje nge-PP, PE, i-PE, i-PE, i-PET, njl. Njl njl.

I-rannication yeplastiki ye-granung

I-1.Benater Dewaters viberation Ukudibanisa kunye nohlobo lwe-centrifal ye-centrigual debetals yangoku intsebenzo ephezulu kunye nokusetyenziswa kwamandla asezantsi.

2. I-Ceves ehlanganisiweyo: I-SEEves ifakiwe kwaye ilungiswe zizikrelemnqa endaweni ye-welding, ukuze utshintshe amaxabiso ngokulula kwixesha elizayo.

Inkqubo ye-granunter yeplastiki yokuphola

Isetyenziselwa ukususa umswakama ukusuka kwi-brace zeplastiki

Inkqubo yokusika i-granurounter

Isetyenziselwa ukusika imitya yeplastiki kumasuntswana

Isikrini sokugcwalisa

Isetyenziselwe ukwahlula ubungakanani be-sundeles zeplastiki