Ukuphinda kufundethwe iplastiki kuyeyona nto ibalulekileyo kwiHlabathi yanamhlanje ngenxa yenkxalabo eyandayo malunga nokuzinza kwendalo. Ukuphinda usebenzise inkunkuma inceda ukunciphisa ungcoliseko, kulondoloze ubutyebi bendalo, kwaye kuncitshiswe isixa seplastiki esiphelela kwiplastiki okanye iilwandlekazi. Kwinkqubo yokurisayikili yeplastiki, inyathelo elinye elibalulekileyo lomisa inkunkuma yeplastiki ngaphambi kokuba iqhubekiwe okanye ukuyifumana. Kulapho kurisayikililikisi yeplastiki equlatha umatshini wokuloma kweplastiki kudlala indima ebalulekileyo.

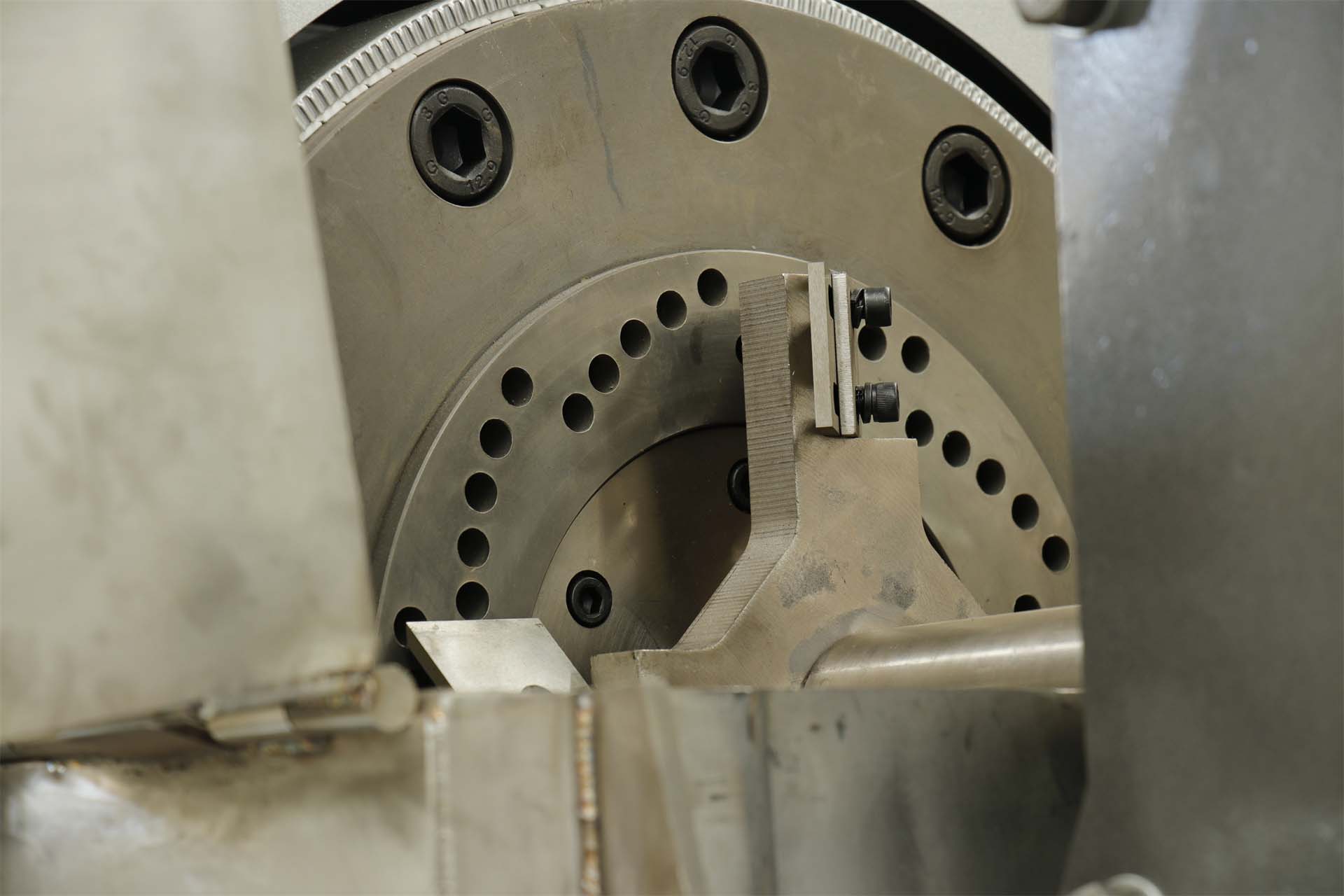

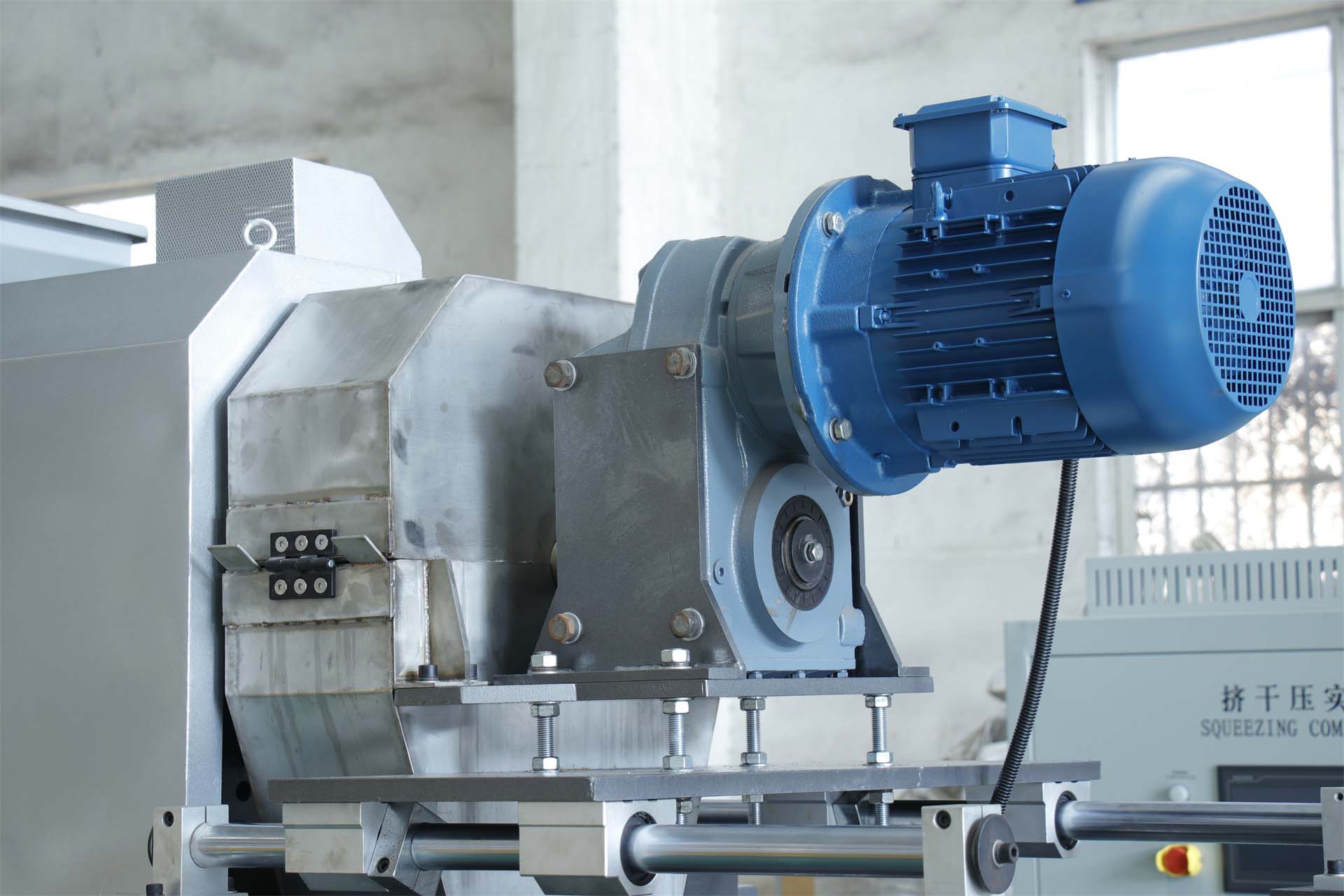

I-plating yokuphinda isebenze iplastiki icekeceke umatshini owomileyo wezomileyo isebenzisa indibaniselwano yeenkqubo zoomatshini kunye ne-thermal yokufezekisa ukomisa okufanelekileyo. Umatshini uqulathe i-hopper okanye i-Infer ye-Inlet apho kungeniswe khona inkunkuma yeplastiki emanzi. Inkunkuma yeplastiki emva koko idluliselwe kwi-scloer ye-screyw okanye indlela ye-auntir, esebenza uxinzelelo kwimibandela, inyanzela umswakama.

Isenzo sokuhambisa i-skieling somshini icinezela inkunkuma yeplastiki kwaye idala imeko yoxinzelelo oluphezulu, ukugxotha amanzi okanye eminye imixholo yolwelo. Ezinye iimodeli zinokubandakanya nezinto zokufudumeza okanye iindlela zokudlulisela ubushushu ukukhawulezisa inkqubo yokomisa. Ubushushu bunceda ekuphumezeni umswakama, kwaye umphunga wamanzi ophumeleleyo uqhelene nomatshini.

Ukuphinda kusetyenziswelwe iplastiki yokuphinda kusetyenziswe iplastiki ye-storter yenzelwe ukuphatha iintlobo ezahlukeneyo zenkunkuma yeplastiki, kubandakanya i-Pelythylene Tolythylene), i-Polythylene Telythylene), i-Polythylene Tolythylene), i-PVC (PVC (POLCIYL chloride), nangaphezulu. Oomatshini banokufumana iindlela ezahlukeneyo zenkunkuma, ezinje ngeebhotile, izikhongozeli, iifilimu, kunye neempahla zeplastiki ezikhutshiwe.

Izibonelelo zokusebenzisa iplastiki yokuphinda iphinde iphinde iphinde isebenze

Ukuphuculwa kokusebenza kakuhle:Ngokunciphisa umxholo womswakama, umatshini ufezekisa iinkqubo zokurisayikisisha, ezinje ngokushukumisa, ukupheliswa, okanye ipellet. Inkunkuma yeplastiki eyomileyo ilula ukuyiphatha kwaye inempawu ezihamba phambili, ezikhokelela kwimveliso yokuvelisa kunye nokunciphisa ukusetyenziswa kwamandla.

Umgangatho ophuculweyo weplastiki ehlaziyiweyo:Iplastiki ye-moricure-free ineepropathi ezingcono zomzimba, iqinisekisa ukuba iplastiki ehlaziyiweyo ihlangabezana nemigangatho yomgangatho oyifunayo. Ingasetyenziselwa izicelo ezahlukeneyo, kubandakanya ukwenza imveliso yeplastiki entsha okanye njengezinto eziluhlaza kwamanye amashishini.

Impembelelo yokusiNgqongileyo:Ngokwenza inkunkuma ngempumelelo yeplasitiki, umatshini wokuphinda usebenzise i-pieting queering igalelo ekunciphiseni ifuthe lokuphinda kwenziwe iplastiki. Inciphisa isidingo samanyathelo owomileyo owomayo, ulondolozwa amandla, kwaye ikhuthaza indlela ezinzileyo kulawulo lwenkunkuma yeplastiki.

Ukutshintsha:Umatshini unokuphatha iintlobo ezahlukeneyo kunye neefom zenkunkuma yeplastiki, ekudluliselwe kwimisebenzi yokurisayikilisha. Inokuqhubela ubungakanani obahlukeneyo kunye nemilo yezinto zeplastiki, ezihlengahlengiswa kwiimfuno ezithile zamaziko ahlukeneyo okurisayikilisha.

Ukuqukumbela, ukurisayikilisha kwakhona iplastiki equlathe umatshini wokumisa i-slooring yinxalenye yenkqubo yokuphinda isebenze yeplastiki. Ngokususa ukufuma ngokusuka kwinkunkuma yeplastiki, iphucula umgangatho weplastiki ehlaziyiweyo, iphucula ukuvelisa, kwaye ixhasa iinkqubo zokulawula inkunkuma ezizinzileyo. Ngogxininiso olukhulayo kulondolozo lwendalo, ukusetyenziswa kwaba matshini kubalulekile ekukhuthazeni uqoqosho olufutshane kunye nokunciphisa ifuthe lemo engqongileyo yenkunkuma.

I-Post Time: Aug-01-2023