I-shaft eyodwa shredder

I-shaft eyodwa shredder

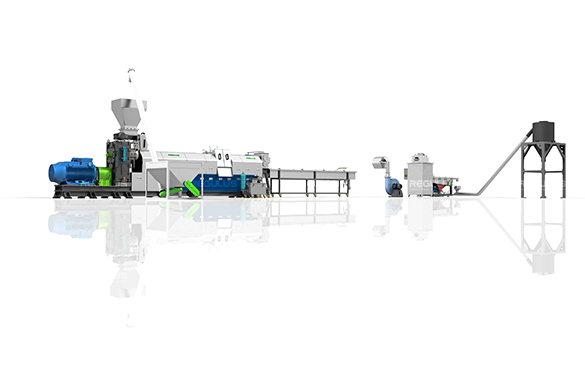

Ilungele ukuphinda usebenzise uluhlu lwezinto ezibanzi. Ngumtshini ofanelekileyo weplastiki, iphepha, ifayibha, irabha, inkunkuma ye-organic kunye neentlobo ezahlukeneyo zezixhobo. Ngokweemfuno zabathengi bethu, ezinjengobukhulu be-inzuzo yezinto ezibonakalayo, ubungakanani kunye nobukhulu bemveliso yokugqibela njl., Sinokusebenza isindululo esifanelekileyo sabaxumi bethu. Emva kokutshintshwa ngumatshini, izinto eziphumayo zinokusetyenziswa ngokuthe ngqo okanye ukuya kwinqanaba elilandelayo lokuncitshiswa. Ngokusebenza kwenkqubo yokulawula umbala we-hicrocomputers, kunokwenzeka ukuba ulawule ngokuzenzekelayo, yeka, i-sensers ye-Autartic Refle ukukhusela umatshini ngokuchasene nokutsala.

Isicelo semveliso

| I-1. Ifilimu yeplastiki / ibhegi ye-Wick / Ibhotile yeBhotile yeZilwanyana / Iplastiki yombhobho / Iibhodi zeplastiki / iibhodi zeplastiki | I-2. Iphepha / ibhokisi yekhadibhodi |

| I-3. Iplastiki enzima: iplastikhi yeplastiki / i-puriber / i-fiber / iplastiki ye-Abs, iPC, i-PPS | 4. Iinkuni / zeplanga / iingcambu zomthi / i-pallets zenkuni |

| I-5. I-TOV ye-TOBRY / YOKUZIPHATHA NGOKUGQIBELA | I-6. Isinyithi sokukhanya |

| 7. Inkunkuma eqinileyo: inkunkuma eqinileyo: inkunkuma yasemzini, inkunkuma yasekhaya, inkunkuma yezonyango | 8. Intambo |

Iimveliso zokugqibela

Iimpawu zeMveliso

| I-1. I-Rotor: | Ukucwangciswa kwahlukeneyo eziqengqelekayo kufumaneka ngokwenza uluhlu olubanzi lwezixhobo. Amabala yenziwa kwintsimbi enzima ye-DC53; Amabala anokuguqulwa amaxesha ama-4 ngaphambi kokutshintsha. |

| 2. I-Gearbox: | Amanzi apholileyo opholileyo obandayo ngokuchasene nokulayishwa kakhulu. Amazinyo anzima kunciphiso. |

| I-3. I-Abufunger ye | Ifunxa i-chibings ezibangelwa kukucanyatyalwa kwezinto. Oku kukhusela umatshini kunye neenxalenye zayo ezahlukeneyo zomonakalo. |

| 4. I-RAM: | I-Hydraulic Russive ityhila iimpahla ngokuchasene nomzi. |

| 5. Ukuhlasela: | Ukukhusela inkathazo ukunqanda ungcoliseko lwangaphandle lungenise izindlu zokuzala. I-GAROARS PORS ukuKhupha ioyile ngamaxesha onke ukwandisa ubomi beenkonzo. |

| 6. Isikrini: | Ubungakanani be-screen. |

| 7. Isikhululo se-hydraulic: | I-RAM Ingcinezelo kunye nexesha kufuneka zilungiswe ukuze zihambelane nezixhobo ezahlukeneyo. |

| 8. Iqinisekisiwe: | Izixhobo zokhuseleko zihambelana nokuqinisekiswa kweYurophu |

Iiparamitha eziphambili

I.WT22 / 40 uthotho lwe-shaft engatshatanga

| Imodeli | Wt2260 | Wt4080 | Wt40100 | Wt40120 | Wt40150 |

| Ukusika igumbi c / d (mm) | I-850 * 600 | 1300 * 800 | I-1300 * 1000 | I-1400 * 1200 | I-1400 * 1400 |

| I-Rotor Seameter (MM) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Isantya esiphambili seShaft (R / min) | 83 | 83 | 83 | 83 | 83 |

| Isikrini mesh (mm) | φ40 | φ50 | φ60 | φ60 | φ60 |

| I-Rotor-i-nurgy (PCS) | 28 | 40 | 48 | 61 | 78 |

| Amandla aphambili eemoto (kW) | 22 | 37-45 | 45-55 | 75 | 75-90 |

| I-Hydraulic motor (kW) | 2.2 | 3 | 3 | 5.5 | 7.5 |

II. WT48 uthotho lwe-shaft engatshatanga

| Imodeli | Wt4080 | Wt40100 | Wt40120 |

| Ukusika igumbi c / d (mm) | I-1300 * 1000 | I-1400 * 1200 | I-1400 * 1500 |

| I-Rotor Seameter (MM) | φ480 | φ480 | φ480 |

| Isantya esiphambili seShaft (R / min) | 74 | 74 | 74 |

| Isikrini mesh (mm) | φ60 | φ60 | φ60 |

| I-Rotor-i-nurgy (PCS) | 48 | 61 | 78 |

| Amandla aphambili eemoto (kW) | 45-55 | 75 | 75-90 |

| I-Hydraulic motor (kW) | 3 | 5.5 | 7.5 |

III. I-WTPP40 Sering Pipe-I-Shoft Shoft Shredder:

| Imodeli | I-WTP2260 | Wtp4080 | Wtp40100 | I-WTPP40120120 | I-WTPP40150 |

| Ukusika igumbi c / d (mm) | I-600 * 600 | I-800 * 800 | I-1000 * 1000 | I-1200 * 1200 | I-1500 * 1500 |

| I-Rotor Seameter (MM) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Isantya esiphambili seShaft (R / min) | 83 | 83 | 83 | 83 | 83 |

| Isikrini mesh (mm) | φ40 | φ50 | φ60 | φ60 | φ60 |

| I-Rotor-i-nurgy (PCS) | 28 | 42 | 51 | 63 | 78 |

| Amandla aphambili eemoto (kW) | 22 | 37 | 45 | 55 | 75 |

| I-Hydraulic motor (kW) | 2.2 | 3 | 3 | 5.5 | 7.5 |

Ividiyo yeShaff enye ye-Shored:

Bhala umyalezo apha kwaye uthumele kuthi